302150 Drop In Anchors - 316 Stainless Steel

Drop In Anchors are designed for medium duty use in solid concrete or masonry where the depth of embedment may be limited by reinforcing materials, aggregate, etc., The expander cone encapsulated in the anchor is set using a setting tool to drive it to the bottom of the anchor allowing for minimized hole depths whilst achieving the correct embedment depth. A threaded rod, bolt or stud is then used to complete the fastening. Made from 316SS for use in highly corrosive and/or marine environments.

• Hole depth is minimized

• No restriction on the fixture thickness that can be attached as threaded rod or machine threaded bolts or studs of any length can be used providing an extremely flexible fixing option

• Easy to install

• Can be immediately loaded after installation, no downtime waiting for curing etc.,

• Threaded fastener component can be easily removed leaving the Drop in anchor flush with the substrate surface, threaded component can be re-installed if required

• Minimizes subsurface obstruction problems

• Made from 316 Marine Grade Stainless Steel provides a long life fixing with extremely high Corrosion Resistance

• High Fire and Heat Resistance - Retains strength under harsh and extreme temperature conditions

• Hygienic- Easy to clean and sanitise

• Impact Resistance and strength - extremely tough and highly durable material with high impact resistance

• Available in a wide range of sizes

• No restriction on the fixture thickness that can be attached as threaded rod or machine threaded bolts or studs of any length can be used providing an extremely flexible fixing option

• Easy to install

• Can be immediately loaded after installation, no downtime waiting for curing etc.,

• Threaded fastener component can be easily removed leaving the Drop in anchor flush with the substrate surface, threaded component can be re-installed if required

• Minimizes subsurface obstruction problems

• Made from 316 Marine Grade Stainless Steel provides a long life fixing with extremely high Corrosion Resistance

• High Fire and Heat Resistance - Retains strength under harsh and extreme temperature conditions

• Hygienic- Easy to clean and sanitise

• Impact Resistance and strength - extremely tough and highly durable material with high impact resistance

• Available in a wide range of sizes

Step 1:-

Select the correct size IDEAL Fasteners Carbide drill bit for your chosen diameter and length of Drop In Anchor.

Step 2:-

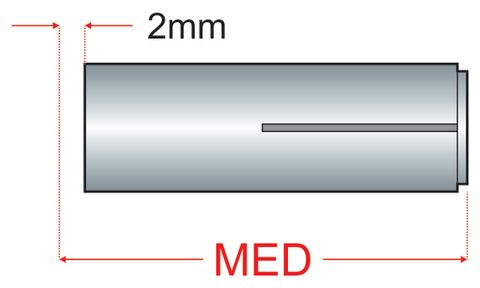

Using a Rotary Hammer tool or a suitable Impact tool, drill the correct size hole into the concrete or masonry substrate to a depth of a minimum of 2mm longer than the fastener length, clean the hole thoroughly with a wire brush, vacuum and/or blow pump.

Avoid drilling the hole too close to the edge of the masonry as the expansion action of the anchor during installation may cause splitting of the masonry.

Step 3:-

Place the anchor into the hole with the threaded end facing outwards, tap the anchor lightly to ensure it is seated in the bottom of the hole.

Step 4:-

Using the correct size setting tool for the size of Drop In anchor used, place the smaller diameter end of the tool into the threaded end of the anchor.

Step 5:-

Strike the end of the setting tool with a hammer until the step in the shank of the setting tool contacts the top of the anchor, at this point the anchor is set and ready to receive the mating threaded rod etc.,

Step 6:-

Place the threaded rod, bolt or stud in the Drop In Anchor and tighten to a snug fit and then nip up until firmly secured., DO NOT overtighten.

Select the correct size IDEAL Fasteners Carbide drill bit for your chosen diameter and length of Drop In Anchor.

Step 2:-

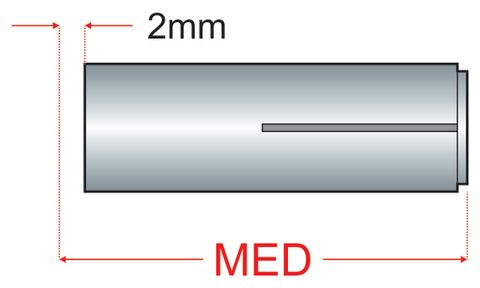

Using a Rotary Hammer tool or a suitable Impact tool, drill the correct size hole into the concrete or masonry substrate to a depth of a minimum of 2mm longer than the fastener length, clean the hole thoroughly with a wire brush, vacuum and/or blow pump.

Avoid drilling the hole too close to the edge of the masonry as the expansion action of the anchor during installation may cause splitting of the masonry.

Step 3:-

Place the anchor into the hole with the threaded end facing outwards, tap the anchor lightly to ensure it is seated in the bottom of the hole.

Step 4:-

Using the correct size setting tool for the size of Drop In anchor used, place the smaller diameter end of the tool into the threaded end of the anchor.

Step 5:-

Strike the end of the setting tool with a hammer until the step in the shank of the setting tool contacts the top of the anchor, at this point the anchor is set and ready to receive the mating threaded rod etc.,

Step 6:-

Place the threaded rod, bolt or stud in the Drop In Anchor and tighten to a snug fit and then nip up until firmly secured., DO NOT overtighten.

• Ideal for use in overhead ceiling suspension applications including suspended ceilings, cable trays, pipes, ductwork, sprinkler systems etc., where aggregate often settles towards the underside of the slab during the curing process or reinforcing mate

| Size | Coating | Pack Type | 560 Y Drill Size | 590 Y Min. Embedment Depth | 600 Y Internal Thread | Code |

|---|---|---|---|---|---|---|

| M6 x 25mm |

|

|||||

| M8 x 30mm |

|

|||||

| M10 x 40mm |

|

|||||

| M12 x 50mm |

|

|||||

| M16 x 65mm |

|