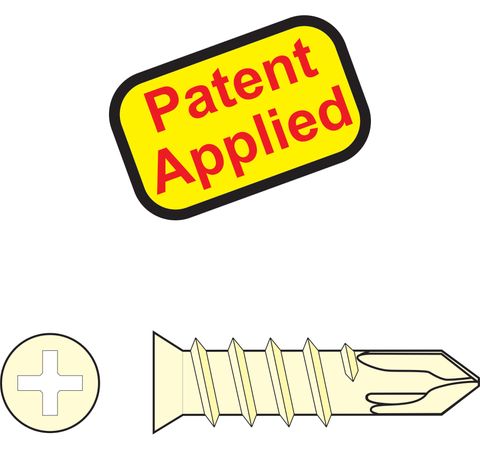

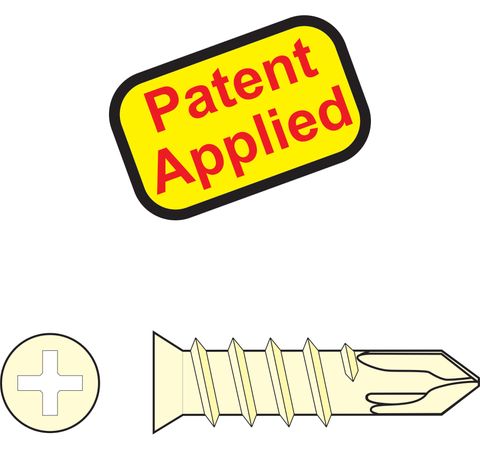

120350 SteelMates® - GrubMates®

An innovative, new invention designed for fixing Fibre cement sheet as thin as 4~4.50mm to steel as thin as 0.42mm thick in steel frame construction. Featuring the Patented GrubMates technology these screws provide extremely high strip torque and holding power. The unique design virtually eliminates damage to the FCB and needs little or no surface maintenance nor repairs prior to painting. Sandstone Colour matched to provide improved aesthetics with EP++ coating for high corrosion resistance.

• Fast and easy to instal

• High resistance to the fibre cement board pulling over the head of the screw

• Eliminates mushrooming, volcanoeing, splitting and damage of the fibre cement board as the head embeds

• Can be set to finish flush or below the surface of the FCB

• Eliminates sanding and surface preparation prior to painting

• High Shear Strength

• High Withdrawal Strength

• High Tensile Strength

• High Strip Torque

• Complies with AS3566.1 & 2

• High resistance to the fibre cement board pulling over the head of the screw

• Eliminates mushrooming, volcanoeing, splitting and damage of the fibre cement board as the head embeds

• Can be set to finish flush or below the surface of the FCB

• Eliminates sanding and surface preparation prior to painting

• High Shear Strength

• High Withdrawal Strength

• High Tensile Strength

• High Strip Torque

• Complies with AS3566.1 & 2

1/ Ensure the correct driver tool is fitted to your power drill or screw driver.

2/ Place the screw on the driver tool and position it onto the materials being fastened.

3/ If necessary push sharply to create a centre mark and to prevent screw wander.

4/ Squeeze and tap trigger and maintain steady, constant pressure until the screw has drilled and fastened.

Recommended Driving speed is approximately 1,000 r.p.m.

2/ Place the screw on the driver tool and position it onto the materials being fastened.

3/ If necessary push sharply to create a centre mark and to prevent screw wander.

4/ Squeeze and tap trigger and maintain steady, constant pressure until the screw has drilled and fastened.

Recommended Driving speed is approximately 1,000 r.p.m.

• Ideal for fixing fibre cement eaves and soffit linings, bracing boards or thin timber panelling or sheeting to thin steel substrates.

| Size | Coating | Pack Type | 500 Y Drilling Capacity in Steel | 520 Y Thread Length (TL) | 530 Y Driver Tool | Code |

|---|---|---|---|---|---|---|

| 12g x 20mm |

|