610155 Pilot Point Bolt Bracing Strap Tensioner System

Stock Code:

BSTPPB

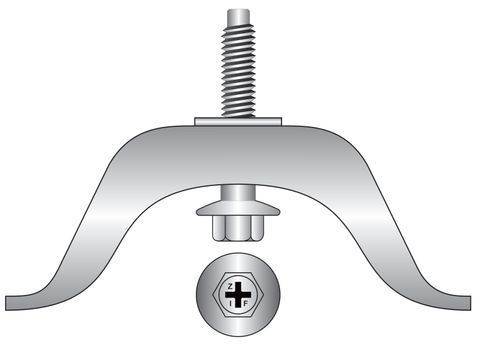

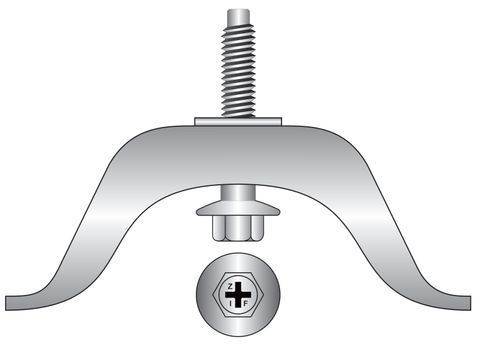

The sister system to the SDB system is the Pilot Point Bolt (PPB) Bracing Strap Tensioner system for use in pre-punched strap. Competing systems currently available can be rather fiddly to locate the point of the bolt into the threaded tensioner Learning from the success of the SDB system, IDEAL developed the unique Pilot point Bolt system which greatly assists in the aligning of the bolt and tensioner eliminating cross threading and making assembly much quicker than competing products.

• Quick and easy to install

• Pilot Point bolt self aligns with the thread in the bracket making alignment extremely quick, avoids jamming and damage due to cross threading of the bolt in the bracket

• Has a combination drive 5/16" Hex with #2 Phillips drive

• Features a convex flanged Hex Washer head which provides the benefits of power driving and/or manual adjusting as well as low driving torque with greater bearing area on, and less damage to, the bracing strap.

• Pilot Point bolt self aligns with the thread in the bracket making alignment extremely quick, avoids jamming and damage due to cross threading of the bolt in the bracket

• Has a combination drive 5/16" Hex with #2 Phillips drive

• Features a convex flanged Hex Washer head which provides the benefits of power driving and/or manual adjusting as well as low driving torque with greater bearing area on, and less damage to, the bracing strap.

1. Fasten the bracing strap at each end in accordance with the manufacturers recommendations and the requirements of the National Construction Code.

2. Ensure the correct IDEAL Fasteners driver tool, a 5/16" Hex Nutsetter or # 2 Phillips drive tip is fitted to the screwdriver, power tool or hand tool and place it on the head of the Self-Drilling or Pilot Point Bolt. It is recommended to use a 5/16" Hex Nutsetter for power driving for easy installation.

3. a} When using the Pilot Point Bolt system

Locate a hole in the centre of the width of the bracing strap equi-distant between supporting wall studs and place the M6 bolt through the hole.

If no holes exist in the bracing strap a 6.00mm hole will need to be drilled or punched central to the strap width.

b) When using Self-Drilling Bolt system

i) If using pre-punched strap, or wanting to manually place a hole in the strap, follow the instructions in point 3 a) above.

ii) If using unpunched strap and utilising the self drilling function of this assembly then:-

• Fit the Self-Drilling Bolt onto an electric or cordless screw driver or impact driver.

• Place the drill point in the centre of the width of the bracing strap equi-distant between supporting wall studs.

• Squeeze the trigger and maintain constant pressure whilst driving the Self-Drilling Bolt at approximately 2,000 r.p.m. until it has drilled and completed threading through the bracing strap far enough to allow the tensioner to be attached.

4. Place the tensioner against the bracing strap ensuring the tensioner is within the wall frame cavity and thus will leave a flush external finish after tensioning. Locate the tensioner over the point of the bolt and hold the tensioner in place taking care to ensure it does not rotate during tightening.

Note:

Appropriate safety gloves and PPE must be worn and care must be taken to ensure the point of the bolt does not come into contact with hands nor fingers.

5. Squeeze the screwdriver trigger gently until the bolt is driven to the point where the strap is taut and no slack remains. Do not over tighten. If slack remains a second tensioner should be used at a distance remote from the first by at least one spacing of the wall studs.

Note:-

Bracing Strap tensioners are designed solely for the purpose of pre-tensioning the strap prior to fastening and do not negate the need to fasten the strap to the wall studs after tensioning.

Tensioners are not designed to be used for plumbing or squaring up the frames.

6. Fasten the bracing strap at each intersection with studs or other members in accordance with the manufacturers recommendations and the requirements of the NCC.

2. Ensure the correct IDEAL Fasteners driver tool, a 5/16" Hex Nutsetter or # 2 Phillips drive tip is fitted to the screwdriver, power tool or hand tool and place it on the head of the Self-Drilling or Pilot Point Bolt. It is recommended to use a 5/16" Hex Nutsetter for power driving for easy installation.

3. a} When using the Pilot Point Bolt system

Locate a hole in the centre of the width of the bracing strap equi-distant between supporting wall studs and place the M6 bolt through the hole.

If no holes exist in the bracing strap a 6.00mm hole will need to be drilled or punched central to the strap width.

b) When using Self-Drilling Bolt system

i) If using pre-punched strap, or wanting to manually place a hole in the strap, follow the instructions in point 3 a) above.

ii) If using unpunched strap and utilising the self drilling function of this assembly then:-

• Fit the Self-Drilling Bolt onto an electric or cordless screw driver or impact driver.

• Place the drill point in the centre of the width of the bracing strap equi-distant between supporting wall studs.

• Squeeze the trigger and maintain constant pressure whilst driving the Self-Drilling Bolt at approximately 2,000 r.p.m. until it has drilled and completed threading through the bracing strap far enough to allow the tensioner to be attached.

4. Place the tensioner against the bracing strap ensuring the tensioner is within the wall frame cavity and thus will leave a flush external finish after tensioning. Locate the tensioner over the point of the bolt and hold the tensioner in place taking care to ensure it does not rotate during tightening.

Note:

Appropriate safety gloves and PPE must be worn and care must be taken to ensure the point of the bolt does not come into contact with hands nor fingers.

5. Squeeze the screwdriver trigger gently until the bolt is driven to the point where the strap is taut and no slack remains. Do not over tighten. If slack remains a second tensioner should be used at a distance remote from the first by at least one spacing of the wall studs.

Note:-

Bracing Strap tensioners are designed solely for the purpose of pre-tensioning the strap prior to fastening and do not negate the need to fasten the strap to the wall studs after tensioning.

Tensioners are not designed to be used for plumbing or squaring up the frames.

6. Fasten the bracing strap at each intersection with studs or other members in accordance with the manufacturers recommendations and the requirements of the NCC.

• Used in conjunction with bracing strap for tensioning of frames in steel and/or timber framed buildings.