300200 Scru-Bolts™ - Hex Head, Zinc & Galv.

These anchors provide improved performance over traditional expansion type anchors as there is no expansion of the anchor so they can be used much closer to edges without splitting the masonry. They are fast to install and easy to use as the fastener taps its own mating thread directly into the masonry. Easy to remove quickly with no damage to the substrate leaving only the drill hole to patch if required. Stocks are limited as this range is being superseded by the Hex Flange head Scru-BoltsTM.

• Can be used closer to edges than expansion type anchors.

• Extremely fast and easy to install

• Can be immediately loaded after installation, no downtime waiting for curing etc.,

• Can be easily removed

• High Shear Strength

• High Withdrawal Strength

• High Tensile Strength

• Available in a range of sizes, lengths and coatings for a multitude of applications both internally and externally

• Extremely fast and easy to install

• Can be immediately loaded after installation, no downtime waiting for curing etc.,

• Can be easily removed

• High Shear Strength

• High Withdrawal Strength

• High Tensile Strength

• Available in a range of sizes, lengths and coatings for a multitude of applications both internally and externally

Step 1:-

Select the correct size IDEAL Fasteners Carbide drill bit for your chosen diameter and length of Scru-Bolt™.

Note: Do not use the same drill bit nor drill size to drill the hole through the fixture being attached, regardless of whether that fixture is steel, timber or any other material.

There must be a clearance hole in the material being fixed that has a diameter of at least 2.0mm greater than the outside diameter of the thread on the Scru-Bolt™.

Step 2:-

Using a Rotary Hammer tool or a suitable Impact tool, drill a hole into the concrete or masonry substrate to a depth of at least that of your maximum intended embedment depth of the Scru-Bolt™ PLUS an additional depth of at least 1 to 1.5 times the diameter of the specific Scru-Bolt™ being used.

Step 3:-

Using a blow pump or vacuum, clean the hole until all dust and/or contaminants have been exhausted.

Step 4 :-

Using a wire brush, brush out the hole thoroughly.

Step 5:-

Repeat Step 2.

Step 6:-

With the fixture in place insert the Scru-Bolt™ through the hole in the fixture and into the hole in the substrate.

Step 7:-

Ensure the correct size socket is attached to your driver and place it onto the head of the Scru-Bolt™.

Step 8:-

Rotate the driving tool slowly in a clockwise direction with firm end load pressure until the self tapping action of the threads in the substrate has commenced and the Scru-Bolt™ starts taking a firm hold.

Step 9:-

Tighten the fastener until the connection is a snug fit between the fastener head, the fixture and the substrate and firmly secured, DO NOT over torque the Scru-Bolt™ during installation .

If excessive resistance or driving torque is encountered during the installation process stop driving, reverse the Scru-Bolt™ one or two turns and then re-tighten.

DO NOT overdrive the Scru-Bolt™ when seating it home.

Select the correct size IDEAL Fasteners Carbide drill bit for your chosen diameter and length of Scru-Bolt™.

Note: Do not use the same drill bit nor drill size to drill the hole through the fixture being attached, regardless of whether that fixture is steel, timber or any other material.

There must be a clearance hole in the material being fixed that has a diameter of at least 2.0mm greater than the outside diameter of the thread on the Scru-Bolt™.

Step 2:-

Using a Rotary Hammer tool or a suitable Impact tool, drill a hole into the concrete or masonry substrate to a depth of at least that of your maximum intended embedment depth of the Scru-Bolt™ PLUS an additional depth of at least 1 to 1.5 times the diameter of the specific Scru-Bolt™ being used.

Step 3:-

Using a blow pump or vacuum, clean the hole until all dust and/or contaminants have been exhausted.

Step 4 :-

Using a wire brush, brush out the hole thoroughly.

Step 5:-

Repeat Step 2.

Step 6:-

With the fixture in place insert the Scru-Bolt™ through the hole in the fixture and into the hole in the substrate.

Step 7:-

Ensure the correct size socket is attached to your driver and place it onto the head of the Scru-Bolt™.

Step 8:-

Rotate the driving tool slowly in a clockwise direction with firm end load pressure until the self tapping action of the threads in the substrate has commenced and the Scru-Bolt™ starts taking a firm hold.

Step 9:-

Tighten the fastener until the connection is a snug fit between the fastener head, the fixture and the substrate and firmly secured, DO NOT over torque the Scru-Bolt™ during installation .

If excessive resistance or driving torque is encountered during the installation process stop driving, reverse the Scru-Bolt™ one or two turns and then re-tighten.

DO NOT overdrive the Scru-Bolt™ when seating it home.

• Ideal for fixing in concrete, brick, hollow brick and block.

• Recommended for fixing bottom plates to concrete slabs in timber frame housing.

• Recommended for fixing bottom plates to concrete slabs in timber frame housing.

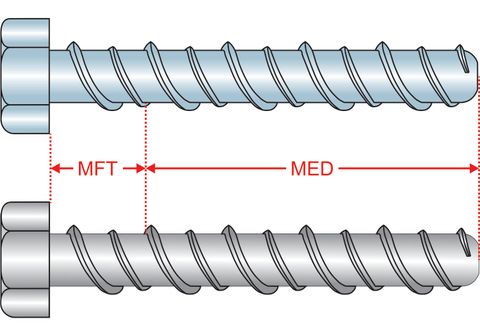

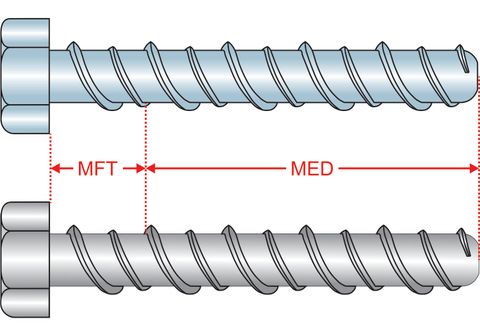

| Size | Coating | Pack Type | 530 Y Driver Tool | 560 Y Drill Size | 580 Y Max. Fixture Thickness | 590 Y Min. Embedment Depth | Code |

|---|---|---|---|---|---|---|---|

| M6 x 30mm |

|

||||||

| M6 x 50mm |

|

||||||

| M6 x 75mm |

|

||||||

| M6 x 100mm |

|

||||||

| M8 x 50mm |

|

||||||

| M8 x 65mm |

|

||||||

| M8 x 75mm |

|

||||||

| M8 x 100mm |

|

||||||

| M10 x 75mm |

|

||||||

| M10 x 100mm |

|

||||||

| M10 x 125mm |

|

||||||

| M10 x 150mm |

|

||||||

| M12 x 75mm |

|

||||||

| M12 x 100mm |

|

||||||

| M12 x 130mm |

|

||||||

| M12 x 150mm |

|

||||||

| M16 x 100mm |

|

||||||

| M16 x 150mm |

|