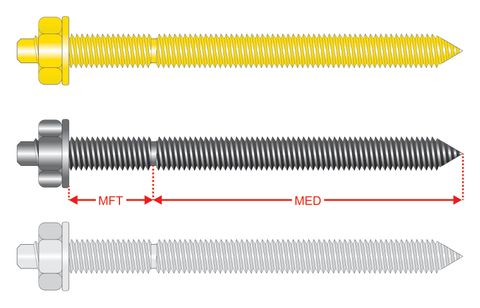

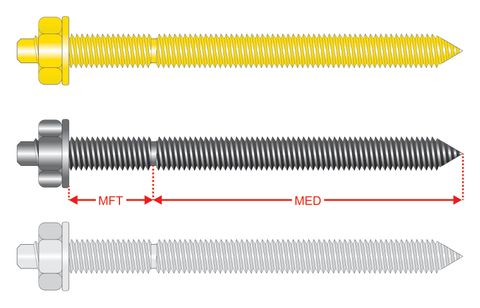

360150 ChemMates™ - Studs:- Zinc Plated, Galvanised & 316 Stainless Steel

Designed for use with Adhesive anchors ChemMates™ Stud assemblies feature a chisel point, an internal hex drive and a free driver tip is provided with each standard pack of studs. ChemMates™ adhesive anchoring systems provide an excellent solution for heavy duty critical applications fastening into concrete and masonry Select from Zinc plated for internal use, galvanized for external use or 316 Stainless Steel for marine and other highly corrosive environments.

For use in conjunction with IDEAL VSF+ ChemMates™

• High bond strength with High load resistance

• Can be used with all grades of threaded rods & rebar in accordance with TR029 and for post installed rebar under TR029 & TR023

• ETA approved for use in non-cracked and cracked concrete

• Features close edge distance and small spacing

• Can be used in dry and wet concrete

• Can be used in critical or overhead applications

• Can be used in corrosive environments

• High durability, good chemical resistance

• Can be used for elevated temperatures - temperature ranges I, II and III

• Fast gelling and curing

• Low Odour

• Styrene free

• Low shrinkage enables large diameter installations

• Fire Rated

• V.O.C. classification A+ Compliant

• Manual cleaning up to 20mm diameter and embedment depths of 240mm

• ETA tested for 50 year anchor life

• Independently tested and approved

• CE certified

• BS6920 approved for use with potable water

• High bond strength with High load resistance

• Can be used with all grades of threaded rods & rebar in accordance with TR029 and for post installed rebar under TR029 & TR023

• ETA approved for use in non-cracked and cracked concrete

• Features close edge distance and small spacing

• Can be used in dry and wet concrete

• Can be used in critical or overhead applications

• Can be used in corrosive environments

• High durability, good chemical resistance

• Can be used for elevated temperatures - temperature ranges I, II and III

• Fast gelling and curing

• Low Odour

• Styrene free

• Low shrinkage enables large diameter installations

• Fire Rated

• V.O.C. classification A+ Compliant

• Manual cleaning up to 20mm diameter and embedment depths of 240mm

• ETA tested for 50 year anchor life

• Independently tested and approved

• CE certified

• BS6920 approved for use with potable water

Step 1:-

Ensure eye protection is worn.

Drill correct hole size & embedment depth.*1

Step 2:-

Just before setting the ChemMates™ anchor the bore hole MUST be thoroughly cleaned and free of dust and debris.

This can be done by 2 methods dependent upon the hole size and depth:-

a) Manual Air Cleaning for all hole diameters ≤ 24mm and bore depth ≤ 10 x the diameter of the steel member (threaded rod or rebar)

The Ideal Fasteners manual pump shall be used for blowing out bore holes up to diameters ≤24mm and embedment depths up to ≤ 10 x the diameter of the steel member.

• Blow out at least 4 times from the back of the bore hole, using an extension if needed.

• Brush 4 times with the specified brush size (see Table B1) by inserting the Ideal Fasteners steel brush to the back of the hole (if needed with an extension) in a twisting motion and removing it.

• Blow out again with manual pump at least 4 times.

b) Compressed Air Cleaning for all bore hole diameters and all bore hole depths

• Blow 2 times from the back of the hole (if needed with a nozzle extension) over the whole length with oil-free compressed air (min. 6 bar at 6 m'/h).

• Brush 2 times with the specified brush size by inserting the Ideal Fasteners steel brush to the back of the hole (if needed with an extension) in a twisting motion and removing it.

• Blow out again with compressed air at least 2 times

Step 3:-

If fixing in hollow material use IDEAL plastic mesh sleeves.

Step 4:-

Remove the threaded cap from the cartridge.

Step 5:-

Tightly attach the mixing nozzle. Do not modify the mixer in any way. Make sure the mixing element is inside the mixer. Use only the supplied mixer.

Step 6:-

Insert the cartridge into the Ideal Fasteners dispenser gun. For the 300ml cartridges a standard silicone gun may be used.

Step 7:-

Pull the trigger and reject first 5 to 10cm until a homogenous colour is achieved, this ensures the two components are fully mixed.

Step 8:-

Fill the hole uniformly starting from bottom, slowly withdrawing the mixer with each trigger pull. Ensure no air pockets exist.

Fill holes approximately 2/3 full to ensure that the annular gap between the anchor and the concrete is completely filled with adhesive along the embedment depth once the steel member is inserted. For deep holes >240mm, use extension tubes & piston plugs.

Step 9:-

Before use, verify that the threaded rod is dry and free of contaminants. Immediately insert rod with a slow, twisting motion, remove excess resin from top of hole.

Follow working and curing times*1. DO NOT move or load anchor until fully cured*1.

*1 Refer to the label on the tube or IDEAL Fasteners Technical Data and/or IDEAL Fasteners ETA17/0776

Ensure eye protection is worn.

Drill correct hole size & embedment depth.*1

Step 2:-

Just before setting the ChemMates™ anchor the bore hole MUST be thoroughly cleaned and free of dust and debris.

This can be done by 2 methods dependent upon the hole size and depth:-

a) Manual Air Cleaning for all hole diameters ≤ 24mm and bore depth ≤ 10 x the diameter of the steel member (threaded rod or rebar)

The Ideal Fasteners manual pump shall be used for blowing out bore holes up to diameters ≤24mm and embedment depths up to ≤ 10 x the diameter of the steel member.

• Blow out at least 4 times from the back of the bore hole, using an extension if needed.

• Brush 4 times with the specified brush size (see Table B1) by inserting the Ideal Fasteners steel brush to the back of the hole (if needed with an extension) in a twisting motion and removing it.

• Blow out again with manual pump at least 4 times.

b) Compressed Air Cleaning for all bore hole diameters and all bore hole depths

• Blow 2 times from the back of the hole (if needed with a nozzle extension) over the whole length with oil-free compressed air (min. 6 bar at 6 m'/h).

• Brush 2 times with the specified brush size by inserting the Ideal Fasteners steel brush to the back of the hole (if needed with an extension) in a twisting motion and removing it.

• Blow out again with compressed air at least 2 times

Step 3:-

If fixing in hollow material use IDEAL plastic mesh sleeves.

Step 4:-

Remove the threaded cap from the cartridge.

Step 5:-

Tightly attach the mixing nozzle. Do not modify the mixer in any way. Make sure the mixing element is inside the mixer. Use only the supplied mixer.

Step 6:-

Insert the cartridge into the Ideal Fasteners dispenser gun. For the 300ml cartridges a standard silicone gun may be used.

Step 7:-

Pull the trigger and reject first 5 to 10cm until a homogenous colour is achieved, this ensures the two components are fully mixed.

Step 8:-

Fill the hole uniformly starting from bottom, slowly withdrawing the mixer with each trigger pull. Ensure no air pockets exist.

Fill holes approximately 2/3 full to ensure that the annular gap between the anchor and the concrete is completely filled with adhesive along the embedment depth once the steel member is inserted. For deep holes >240mm, use extension tubes & piston plugs.

Step 9:-

Before use, verify that the threaded rod is dry and free of contaminants. Immediately insert rod with a slow, twisting motion, remove excess resin from top of hole.

Follow working and curing times*1. DO NOT move or load anchor until fully cured*1.

*1 Refer to the label on the tube or IDEAL Fasteners Technical Data and/or IDEAL Fasteners ETA17/0776

• For use in conjunction with IDEAL VSF+ ChemMates™ for fixing in concrete, masonry, stone and solid and hollow bricks and blocks and ideal for fixing close to edges.

• Can be used overhead, in corrosive areas, in wet & flooded environments &/or fix

• Can be used overhead, in corrosive areas, in wet & flooded environments &/or fix

| Size | Coating | Pack Type | 560 Y Drill Size | 580 Y Max. Fixture Thickness | 590 Y Min. Embedment Depth | Code |

|---|---|---|---|---|---|---|

| M8 x 110mm |

|

|||||

| M10 x 130mm |

|

|||||

| M12 x 160mm |

|

|||||

| M16 x 190mm |

|

|||||

| M20 x 260mm |

|

|||||

| M24 x 300mm |

|