302100 WedgeMates® - Hex Head, 316 Stainless Steel

WedgeMates™ are a medium to heavy duty general purpose anchor for fixing into concrete, solid brick or concrete block etc., The fully threaded shank allows the one anchor to be used with a range of fixture thicknesses or in holes where obstructions like rebar or reinforcing mesh are encountered, ensure the correct embedment depth is achieved. Made from marine grade 316 Stainless Steel for use in highly corrosive and/or marine environments or where an aesthetically pleasing finish is required.

• The shank diameter of the anchor is the same as the diameter of the hole to be drilled in the substrate, this means the maximum shear strength for a anchor in any given hole size is maximised

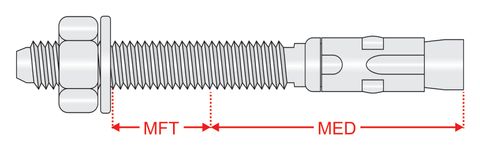

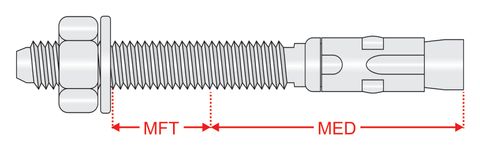

• Fully threaded design accommodates various material thicknesses at the same embedment

• One anchor length saves time and money.

• Eliminates subsurface obstruction problems

• Easy to install

• Can be immediately loaded after installation, no downtime waiting for curing etc.,

• Made from 316 Marine Grade Stainless Steel provides a long life fixing with extremely high Corrosion Resistance

• High Fire and Heat Resistance - Retains strength under harsh and extreme temperature conditions

• Hygienic- Easy to clean and sanitise

• Impact Resistance and strength - extremely tough and highly durable material with high impact resistance

• Bright Silver shiny finish for aesthetic pleasing appearance

• High Shear Strength

• High Withdrawal Strength

• High Tensile Strength

• Available in a wide range of sizes and lengths

• Fully threaded design accommodates various material thicknesses at the same embedment

• One anchor length saves time and money.

• Eliminates subsurface obstruction problems

• Easy to install

• Can be immediately loaded after installation, no downtime waiting for curing etc.,

• Made from 316 Marine Grade Stainless Steel provides a long life fixing with extremely high Corrosion Resistance

• High Fire and Heat Resistance - Retains strength under harsh and extreme temperature conditions

• Hygienic- Easy to clean and sanitise

• Impact Resistance and strength - extremely tough and highly durable material with high impact resistance

• Bright Silver shiny finish for aesthetic pleasing appearance

• High Shear Strength

• High Withdrawal Strength

• High Tensile Strength

• Available in a wide range of sizes and lengths

Step 1:-

Select the correct size IDEAL Fasteners Carbide drill bit for your chosen diameter and length of WedgeMates™ anchor.

Step 2:-

Using a Rotary Hammer tool or a suitable Impact tool, drill a hole into the concrete or masonry substrate to a depth of at least that of your maximum intended embedment depth of the WedgeMates™ anchor PLUS an additional depth of at least 1 to 1.5 times the diameter of the specific WedgeMates™ anchor being used.

Avoid drilling the hole too close to the edge of the masonry as the expansion action of the anchor during installation may cause splitting of the masonry.

Step 3:-

Ensure the hole is clean of all dust and/or contaminants that may obstruct the insertion of the anchor to the required depth. Using a blow pump or vacuum and/or a wire brush is ideal if the dust cannot be sufficiently removed with the drill bit.

Step 4:-

Ensure the material or fixture being attached has a clearance hole wide enough to allow the shank of the anchor to pass through unobstructed.

Step 5:-

Check Hex nut is sufficiently unwound on the WedgeMates™.

Step 6:-

Position the fixture against the substrate with the clearance hole aligned with the drilled hole in the substrate.

Place the WedgeMates™ anchor through the clearance hole and into the hole in the substrate and ensure the minimum embedment depth into the substrate is achieved, if needed a hammer may be used until the head of the anchor contacts the fixture.

Step 7:-

Ensure the correct size driver tool is attached to your hand tool, power drill or driver and place it onto the head of the WedgeMates™ anchor.

Step 8:-

Tighten the fastener until the connection is a snug fit between the fastener head, the fixture and the substrate and then nip up until firmly secured. DO NOT overtighten the WedgeMates™ anchor when seating it home.

Select the correct size IDEAL Fasteners Carbide drill bit for your chosen diameter and length of WedgeMates™ anchor.

Step 2:-

Using a Rotary Hammer tool or a suitable Impact tool, drill a hole into the concrete or masonry substrate to a depth of at least that of your maximum intended embedment depth of the WedgeMates™ anchor PLUS an additional depth of at least 1 to 1.5 times the diameter of the specific WedgeMates™ anchor being used.

Avoid drilling the hole too close to the edge of the masonry as the expansion action of the anchor during installation may cause splitting of the masonry.

Step 3:-

Ensure the hole is clean of all dust and/or contaminants that may obstruct the insertion of the anchor to the required depth. Using a blow pump or vacuum and/or a wire brush is ideal if the dust cannot be sufficiently removed with the drill bit.

Step 4:-

Ensure the material or fixture being attached has a clearance hole wide enough to allow the shank of the anchor to pass through unobstructed.

Step 5:-

Check Hex nut is sufficiently unwound on the WedgeMates™.

Step 6:-

Position the fixture against the substrate with the clearance hole aligned with the drilled hole in the substrate.

Place the WedgeMates™ anchor through the clearance hole and into the hole in the substrate and ensure the minimum embedment depth into the substrate is achieved, if needed a hammer may be used until the head of the anchor contacts the fixture.

Step 7:-

Ensure the correct size driver tool is attached to your hand tool, power drill or driver and place it onto the head of the WedgeMates™ anchor.

Step 8:-

Tighten the fastener until the connection is a snug fit between the fastener head, the fixture and the substrate and then nip up until firmly secured. DO NOT overtighten the WedgeMates™ anchor when seating it home.

• Typical applications include attaching stainless steel and timber members such as brackets, battens, angles etc to concrete, brickwork, masonry etc.,

• Can be used for Guard rails, staircases, balustrades, handrails, ladders, sign posts etc., to con

• Can be used for Guard rails, staircases, balustrades, handrails, ladders, sign posts etc., to con

| Size | Coating | Pack Type | 530 Y Driver Tool | 560 Y Drill Size | 580 Y Max. Fixture Thickness | 590 Y Min. Embedment Depth | Code |

|---|---|---|---|---|---|---|---|

| M8 x 80mm |

|

||||||

| M8 x 90mm |

|

||||||

| M10 x 90mm |

|

||||||

| M10 x 120mm |

|

||||||

| M12 x 80mm |

|

||||||

| M12 x 100mm |

|

||||||

| M12 x 140mm |

|

||||||

| M12 x 150mm |

|

||||||

| M16 x 105mm |

|

||||||

| M16 x 140mm |

|

||||||

| M20 x 125mm |

|

||||||

| M20 x 160mm |

|