306700 Metal Drive Anchors - Round Head

Metal Drive Anchors are a light to medium duty general purpose anchor. Featuring a large diameter head the larger bearing surface provides increased pullover strength. Ideal for tamper resistant applications as the drive nail head finishes encapsulated with the Mushroom fastener head. Made from Zinc Alloy (ZA) material for corrosion resistance Metal Drive anchors also deliver increased strength and load capacities and reduces shearing due to expansion and contraction of materials being fixed.

• Fast and easy to install

• Can be immediately loaded after installation, no downtime waiting for curing etc.,

• Tamper proof and cannot be easily removed

• High Shear Strength

• High Withdrawal Strength

• High Tensile Strength

• Available in a range of sizes and lengths for a multitude of applications

• Made from Zinc Alloy (ZA) material for corrosion resistance, suitable for use both internally and externally

• Can be immediately loaded after installation, no downtime waiting for curing etc.,

• Tamper proof and cannot be easily removed

• High Shear Strength

• High Withdrawal Strength

• High Tensile Strength

• Available in a range of sizes and lengths for a multitude of applications

• Made from Zinc Alloy (ZA) material for corrosion resistance, suitable for use both internally and externally

Step 1:-

Select the correct size IDEAL Fasteners Carbide drill bit for your chosen diameter and length of Metal Drive Anchor.

Step 2:-

Using a Rotary Hammer tool or a suitable Impact tool, drill a hole into the concrete or masonry substrate to a depth of at least that of your maximum intended embedment depth of the Metal Drive Anchor PLUS an additional depth of at least 1 to 1.5 times the diameter of the specific Metal Drive Anchor being used.

Avoid drilling the hole too close to the edge of the masonry as the expansion action of the anchor during installation may cause splitting of the masonry.

Step 3:-

Ensure the hole is clean of all dust and/or contaminants that may obstruct the insertion of the anchor to the required depth. Using a blow pump or vacuum and/or a wire brush is ideal if the dust cannot be sufficiently removed with the drill bit.

Step 4:-

Ensure the material or fixture being attached has a clearance hole wide enough to allow the shank of the anchor to pass through unobstructed.

When attaching fixtures of softwoods or similar density materials to the substrate it may be quicker to use the carbide drill bit to drill a pilot hole in the timber at the same time as drilling the substrate provided the dust can be sufficiently removed from the hole and the fixture is not damaged during installation of the anchor.

Step 5:-

Position the fixture against the substrate with the clearance hole or pilot hole aligned with the drilled hole in the substrate.

Place or drive the Metal Drive Anchor through the hole in the fixture and into the hole in the substrate.

Step 6:-

Using a hammer strike the head of the drive pin until the pin is seated in the head of the anchor and the connection is tight and secure, ensure the minimum embedment depth into the substrate is achieved.

Select the correct size IDEAL Fasteners Carbide drill bit for your chosen diameter and length of Metal Drive Anchor.

Step 2:-

Using a Rotary Hammer tool or a suitable Impact tool, drill a hole into the concrete or masonry substrate to a depth of at least that of your maximum intended embedment depth of the Metal Drive Anchor PLUS an additional depth of at least 1 to 1.5 times the diameter of the specific Metal Drive Anchor being used.

Avoid drilling the hole too close to the edge of the masonry as the expansion action of the anchor during installation may cause splitting of the masonry.

Step 3:-

Ensure the hole is clean of all dust and/or contaminants that may obstruct the insertion of the anchor to the required depth. Using a blow pump or vacuum and/or a wire brush is ideal if the dust cannot be sufficiently removed with the drill bit.

Step 4:-

Ensure the material or fixture being attached has a clearance hole wide enough to allow the shank of the anchor to pass through unobstructed.

When attaching fixtures of softwoods or similar density materials to the substrate it may be quicker to use the carbide drill bit to drill a pilot hole in the timber at the same time as drilling the substrate provided the dust can be sufficiently removed from the hole and the fixture is not damaged during installation of the anchor.

Step 5:-

Position the fixture against the substrate with the clearance hole or pilot hole aligned with the drilled hole in the substrate.

Place or drive the Metal Drive Anchor through the hole in the fixture and into the hole in the substrate.

Step 6:-

Using a hammer strike the head of the drive pin until the pin is seated in the head of the anchor and the connection is tight and secure, ensure the minimum embedment depth into the substrate is achieved.

• Typical applications include fixing of flashings, cappings, downpipe brackets, saddles, signs etc.,

• Has very good tamper resistance attributes

• Has very good tamper resistance attributes

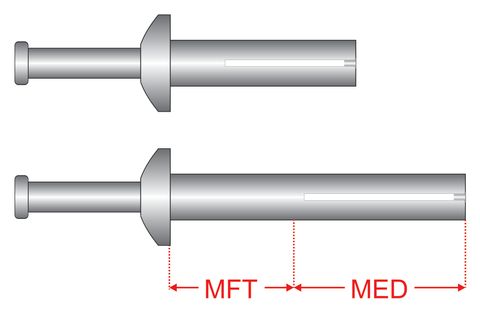

| Size | Pack Type | 480 Y Material | 560 Y Drill Size | 570 Y Head Diam. | 580 Y Max. Fixture Thickness | 590 Y Min. Embedment Depth | Code |

|---|---|---|---|---|---|---|---|

| M5 x 22mm |

|

||||||

| M6.5 x 25mm |

|

||||||

| M6.5 x 32mm |

|

||||||

| M6.5 x 38mm |

|

||||||

| M6.5 x 50mm |

|

||||||

| M6.5 x 75mm |

|