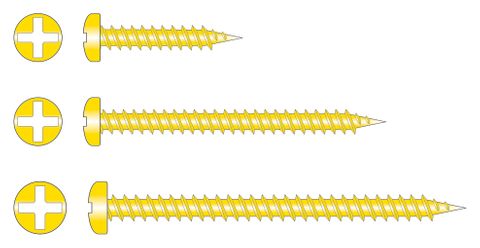

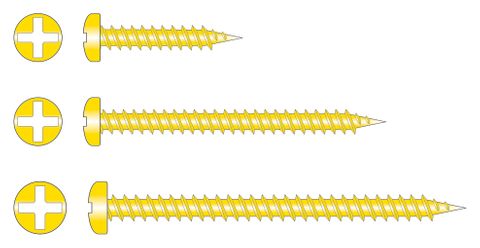

200510 StitchMates® - Pan Head, Needle Point, Twinfast Thread

These screws feature a sharp Needle point for fast drilling when fixing to timber or thin metal up to 0.75mm thick and a Twinfast thread for rapid installation and strong holding power. Featuring a small diameter head these screws fit into small areas with little obstruction caused by the head.

• Small diameter head fits into tight spaces

• Instant piercing

• Fast drilling and easy to use

• Won't skid, wander or slip

• Minimal drilling swarf

• The Zinc Plated finish is recommended for internal use only but can be used externally if adequately painted or protected

• Complies with AS3566.1 & 2

• Instant piercing

• Fast drilling and easy to use

• Won't skid, wander or slip

• Minimal drilling swarf

• The Zinc Plated finish is recommended for internal use only but can be used externally if adequately painted or protected

• Complies with AS3566.1 & 2

1/ Ensure the correct driver tool is fitted to your power drill or screw driver.

2/ Place the screw on the driver tool and position it onto the materials being fastened.

3/ Push sharply to create a centre mark and to prevent screw wander.

4/ Squeeze trigger and maintain steady, constant pressure until the screw has drilled and fastened.

Recommended Driving speed is 1,000 r.p.m for fixing into timber and 2,000+ r.p.m. for fixing into thin metal up to 0.75mm thick.

2/ Place the screw on the driver tool and position it onto the materials being fastened.

3/ Push sharply to create a centre mark and to prevent screw wander.

4/ Squeeze trigger and maintain steady, constant pressure until the screw has drilled and fastened.

Recommended Driving speed is 1,000 r.p.m for fixing into timber and 2,000+ r.p.m. for fixing into thin metal up to 0.75mm thick.

• Recommended for electrical and plumbing applications including conduit clips, brackets and fittings to timber or thin metal up to 0.75mm.

| Size | Coating | Pack Type | 500 Y Drilling Capacity in Steel | 510 Y Rec. Embedment in Timber | 520 Y Thread Length (TL) | 530 Y Driver Tool | Code |

|---|---|---|---|---|---|---|---|

| 6g-18 x 20mm |

|

||||||

| 6g-18 x 30mm |

|

||||||

| 6g-18 x 40mm |

|

||||||

| 6g-18 x 50mm |

|

||||||

| 7g-16 x 12mm |

|

||||||

| 7g-16 x 20mm |

|

||||||

| 7g-16 x 25mm |

|

||||||

| 7g-16 x 30mm |

|

||||||

| 7g-16 x 40mm |

|

||||||

| 7g-16 x 50mm |

|